I.4.

Sequential Injection (SI), the second generation of FIA techniques (Chapter 2), was initially designed for continuous monitoring of industrial processes, where robustness, low reagent consumption, automated calibration and long time stability are the essential requirements (Ruzicka & Marshall 1990). In contrast to other flow based techniques SI is based on discontinuous flow, which is programmed to move forward as well as backward. This reshapes the parabolic flow profile, promotes mixing of the sequentially injected zones and allows reaction rate measurements to be carried out in stop flow mode.

Flow Programming

Flow injection analysis is more than analytical technique.

It is a platform for the majority of analytical methods

G.D.Christian and A.Townshend.

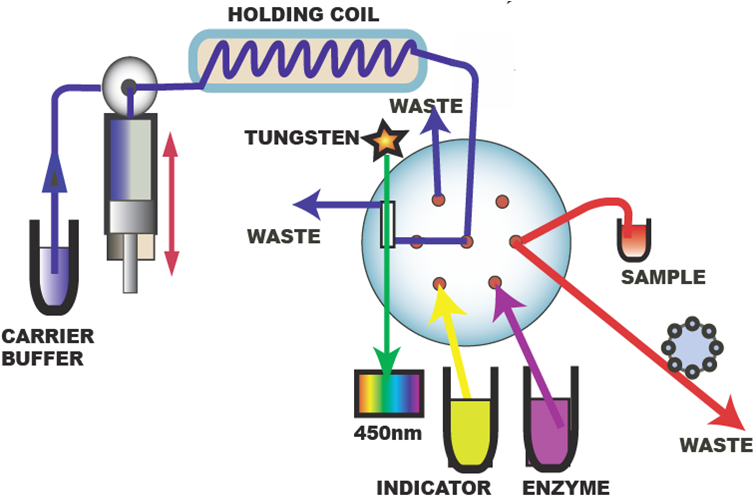

The instrument, shown here in lab-on-valve configuration, comprises a syringe pump, a holding coil a multiposition valve and a flow trough detector. Similar to FI, the SI readout is result of fluidically controlled dispersion and ensuing chemical reactions. Microliter volumes of sample and reagents are sequentially stacked within the holding coil and by following flow reversal transported into the detector. The result is greatly reduced reagent consumption and waste generation since the flow is discontinued between sample injections. SI instruments are produced by FIAlab, and Global FIA.

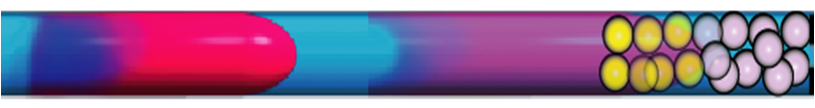

Bead Injection (BI), (Chapter 3) is the variant of SI technique, adapted to handle suspensions with aim to meter, transport, capture, perfuse, monitor and discharge microspheres, such as chromatographic materials in order to miniaturize and facilitate separations‘ trough automated renewal of the stationary. BI spectroscopy is based on monitoring of captured beads, while renewable column separations rely on monitoring of eluted species.

J. Ruzicka & G.D. Marshall, Anal. Chim. Acta, 237, 329, (1990).